Low Friction Plastic

Article

Driving Longer Product Life With Low Friction Plastic

Parts made from low friction polymers can help products last longer with less maintenance. DuPont works with parts-makers and manufacturers worldwide to make moving parts last longer and work better, in applications from automotive drivetrains to conveyors to photovoltaic systems.

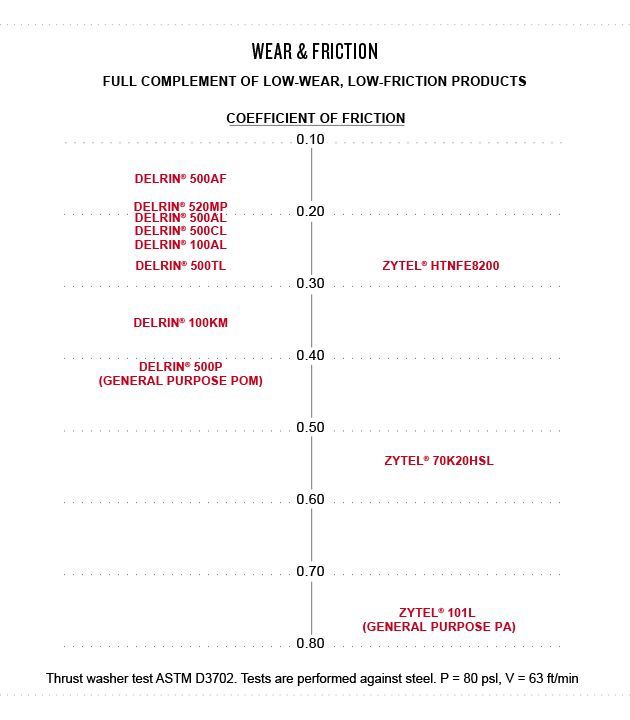

Wear and Friction Chart

Longer-Lasting Parts, Lower Maintenance Costs

DuPont works with engineers, from design to prototype testing and full production, offering material expertise to help them design, manufacture, select and improve products for applications requiring low-wear and/or low friction performance. Optimizing parts for low friction can lead to increased life for critical parts, reduced maintenance costs and quieter operation. Reducing friction between moving parts can also reduce the amount of energy converted to heat, enabling products to perform more efficiently, and to operate at lower temperatures.

- In conveyers and other industrial machinery, the load-bearing capacity can be higher, or the sliding speed can be increased, to make the system more reliable and powerful.

- In automobile applications, reducing friction can lead to reduced fuel consumption and greenhouse gas emission. DuPont polymers and parts can also provide reduced weight, size and complexity than comparable metal parts. This adds to the efficiency of the vehicle by simplifying assembly steps, which leads to overall cost savings.

Delrin® for Conveyors and Car Doors

DuPont™ Delrin® internally lubricated, wear-resistant acetal resins are used to help solve wear, friction or noise problems. They are used in conveyors across a range of industries, from food processing to semi-conductor manufacturing. Delrin® low friction grades allow for a longer lifetime of chains and wear strips, smooth sliding of goods, quieter motion and lubrication-free operations.

Delrin® is also used in car doors by automaker BMW. While the standard steel car door check is lubricated with grease to allow it to move freely, it requires routine maintenance and leaves marks on garments that come in contact with it. BMW, in collaboration with DuPont engineers, identified a high performance alternative using Delrin® 100KM acetal resin, an abrasion-resistant, low friction material modified with Kevlar®.

Delrin® 100KM was used for the cladding on the door checks of BMW’s Series 5, ensuring that the doors open and close smoothly and silently, without lubrication.

Application-Driven Solutions

Delrin® 100KM had to be able to withstand considerable mechanical abuse from the pressure of the rollers on the strip, from the impact at the end of the door’s swing, and from the abrasion caused by every door movement. BMW undertook extensive tests that showed that Delrin® 100KM met the requirements better than all the other materials tested.

Delrin® can also be modified with different technologies, such as Teflon® PTFE, silicone, Kevlar® aramid resin or chemical lubrication, to reduce the wear or the friction in a wide range of applications.

Vespel® Parts For Efficient Transmissions

DuPont™ Vespel® seal rings and thrust washers provide abrasion-resistant, low-friction solutions for ZF Passau’s stepless Eccom CVT transmissions deployed in agricultural machinery from internationally renowned OEMs, such as John Deere, Claas Selbstfahrende Erntemaschinen and Same Deutz-Fahr. Within the transmissions, planet wheels rotate against Vespel® seal rings, instead of cast-iron rings on the drive shafts, to reduce leakage, helping provide reliable, low-maintenance operation.

Fuel Savings And CO2 Reduction

It is estimated that only about 15 percent of the energy in a liter of fuel makes it to the drive wheels, in other words, most is lost to inefficiencies. About 10 percent of this lost energy is attributed to friction between moving parts, equivalent to several million barrels of oil a day.

So it is clear that the ability to reduce friction is extremely important for both existing applications and for the unprecedented number of new powertrain technologies being brought to market today.

Research done at DuPont with Vespel® SP-2515 parts — a graphite-filled polyimide part — instead of PEEK (polyether ether ketone) — demonstrated a 45% to 55% reduction in friction, even at cold temperatures. Finding new applications for low friction plastic could make a significant contribution toward reducing global fuel utilization, and reducing CO2 emissions.