Vespel® CP-0664 Enhances Fan Blade Performance and Durability

Case Study

Vespel® CP-0664 in composite fan blades helps protect the expensive and critical blade root from damage during assembly and operation. The thin fabric construction of Vespel® CP-0664 allows it to conform to a variety of geometries, and its low-friction surface enables consistent fan blade seating at engine startup.

Wear strips made with Vespel® CP-0664 can withstand loads of up to 30ksi that occur during fan blade operation, and they can be easily bonded and repaired if necessary. They also create an insulative barrier between dissimilar metals that prevents galvanic corrosion.

Application

Turbofan jet engine designs utilize single-stage fan blades to introduce air mass flow into compressors. Fan blade materials of construction have evolved over time, from metallic to composites to hybrids. Regardless of the material of construction, one of the biggest challenges is to consistently seat the fan blade root in a predictable and controlled manner.

Challenges

- Balance of a fan blade is an extremely important condition at startup as well as in operation. Due to the high rotational speeds and the mass of materials, any unbalance could seriously impact operation.

- Controlled and predictable fan blade root “seating” at start-up is critical to performance.

- Fan blade root coatings must hold up to repeated high load impacts to avoid excessive damage and wear to root and mating surfaces.

- Fan blade roots may be treated to prevent galvanic and crevice corrosion from occurring at the interface of dissimilar materials.

- Legacy coating systems may not always be easily maintained in the field, thus negatively impacting repair times as well as cost.

- Large components such as fan blades are susceptible to damage during assembly.

Solution

- CP-0664 is a unique composite fabric coating used in a variety of aerospace applications.

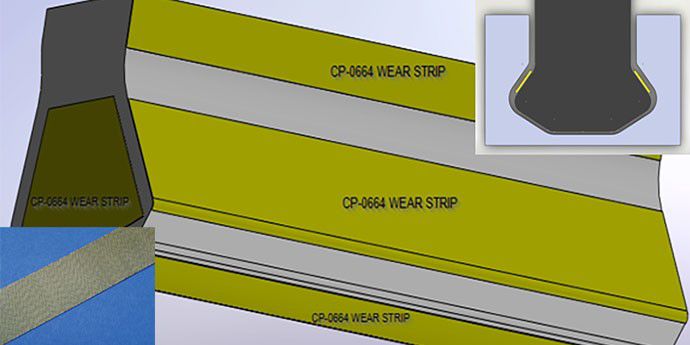

- CP-0664 can be pre-formed to both 2D and 3D geometries for bonding to critical surfaces (Figure 1).

- Pre-formed CP-0664 allows designers to precisely locate and optimize contact surfaces (Figure 1).

- CP-0664 allows for controlled, predictable, and consistent friction performance during blade root seating.

- Composite fabric provides low friction and durable coating to various surfaces while preventing corrosion and damage during assembly.

Features and Benefits

- Wear resistance

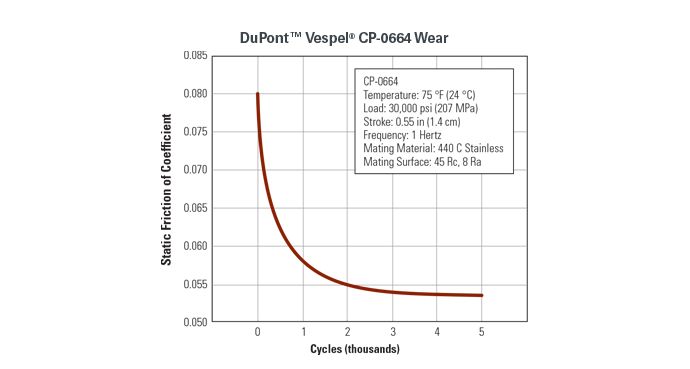

CP-0664 has seen extensive use in jet engine fans and nacelles and proven itself with years of service. Wear testing has been conducted over a variety of test conditions and proven to survive from 7,500 to over 250,000 cycles. A transfer film is created on the mating metal surface which minimizes the wear on both the metal and composite surfaces. - Low friction

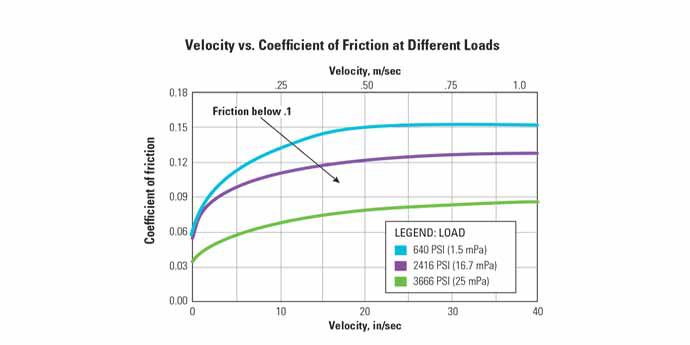

PTFE fibers enhance friction performance, dropping the dynamic coefficient of friction below 0.15. Higher loads only improve frictional behavior (below chart).

- Shear strength/Impact resistance/Durability

CP-0664 was subjected to 70 impacts with a dynamic load of over 150 lb with no visible damage to material or mating components and at performing loads exceeding 30 ksi (below chart).

- Corrosion resistance

CP-0664 has unique composite construction that creates an insulating barrier between dissimilar mating metal surfaces. - Design flexibility

Material can be molded to match unique geometry of most complex designs. Parts can be easily bonded at initial assembly or in the field. - Protects expensive components from wear, helps extend life

Many coatings are brittle, and can be easily damaged in use, or experience corrosion with exposure to normal environmental conditions. CP-0664 has demonstrated ability to protect larger engine components as well as fan blade roots from damage that can lead to costly repairs and removal of engines from service. - Solving a variety of problems

CP-0664 has been used to solve a variety of problems. From v-grooves, fan blade roots, and door/cowl guides to track liners on thrust reversers. The versatility and durability allows you to think out of the box to solve wear and coating problems that are leading to costly repairs on major components.