Vespel® SCP High Temperature Polyimide Parts

Article

In aerospace and industrial applications Vespel® SCP polyimide parts extend the space where high temperature polyimides have been used. Vespel® SCP-5050 and SCP-50094 parts provide higher temperature resistance and a lower coefficient of thermal expansion than traditional polyimides. The filler technology reduces friction and dramatically improves wear resistance versus Vespel® SP-21 parts.

Extended part life

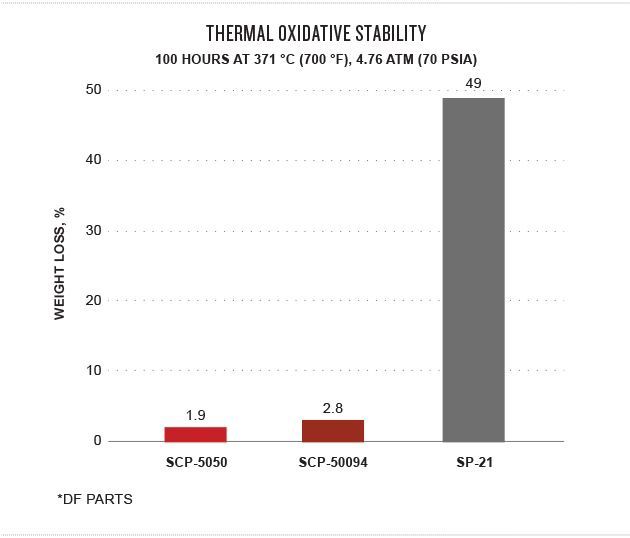

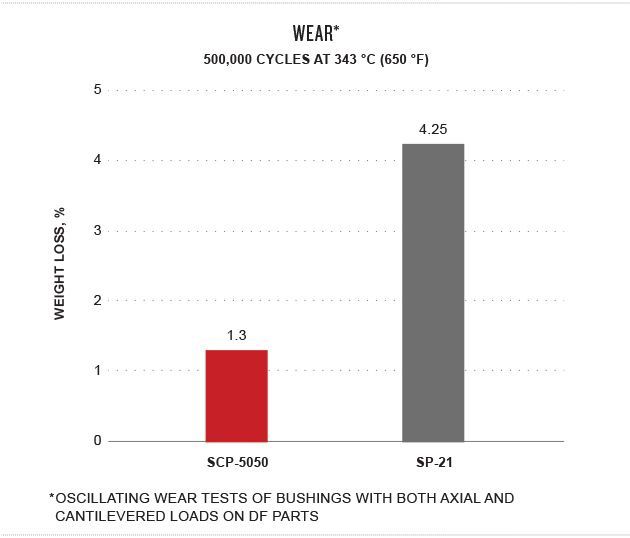

Thanks to their superior thermal oxidative stability (Figure 1) and wear resistance at elevated temperature (Figure 2), Vespel® SCP-5050 and SCP-50094 parts can last longer than traditional polyimides in high temperature wear environments.

Lighter weight

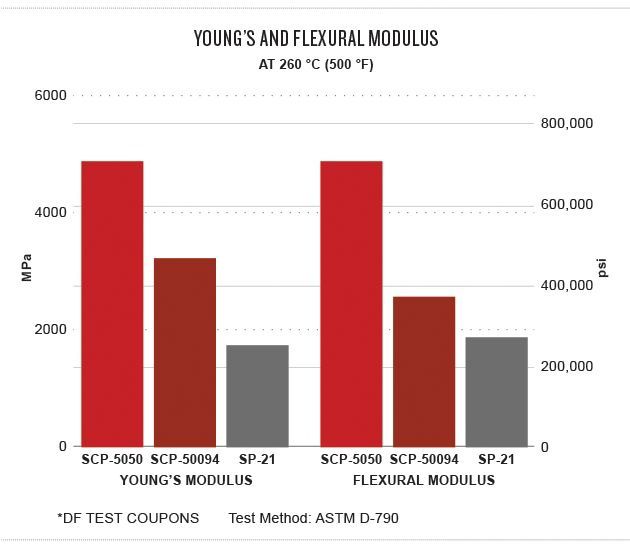

Vespel® SCP-5050 and SCP-50094 parts to save weight by replacing metal in more high temperature environments. Both are much stiffer than traditional filled polyimides at elevated temperature (Figure 3). Their low coefficient of thermal expansion allows closer fits and easier-to-manage tolerance stackups. The CTE of SCP-5050 parts is a near match for that of stainless steel.

Fig. 1 Superior heat stability

Reduced costs

Replacing metal with Vespel® SCP-5050 or SCP-50094 parts can save on both initial and lifetime costs.Lower initial cost than hard-faced or specially treated metallic wear components.

Less wear on mating high-value components jet engine stators for example can sharply cut maintenance costs.

Fig 2. Wear Resistance

What to make of them

DuPont™ Vespel® SCP-5050 and SCP-50094 parts deliver major benefits in aerospace and other industries.

Jet engines: Leading global manufacturers use Vespel® SCP-5050 and SCP-50094 parts in engine applications, upgrading the wear performance of traditional polyimide parts and replacing metal parts in high temperature environments where traditional polyimides have not been used because of previous temperature limitations. Typical applications include wear pads and strips, thrust washers, bushings, bearings, bumpers and more.

Fig 3. Stiff When Hot

Other aerospace uses: The outstanding wear performance of Vespel® SCP parts can also provide benefits where temperatures are less severe than within the engines. Examples include control linkage components, door mechanisms, bushings, bearings, bumpers, wear pads and thrust washers.

Other industries: Vespel® SCP-5050 and SCP-50094 parts are delivering cost and performance benefits in vehicles, as well as industrial equipment requiring higher temperature capabilities, wear resistance and dimensional stability than traditional polyimides and metal bearings.

In glass manufacturing, SCP-5050 exhibits lower thermal conductivity and oil absorption while offering higher impact and wear resistance than conventional glass bottling components

For seals, insulators and more:

An unfilled grade in the SCP series, Vespel® SCP-5000 uses the same base polyimide as SCP-5050 and SCP-50094. It delivers major benefits in applications such as insulators requiring dielectric properties or seals and valve seats needing enhanced high-temperature performance and chemical compatibility.

DuPont has the right materials, technology and technical resources to help you design and manufacture superior parts and systems.