Vespel® Brings High-Temperature Performance to Aircraft Bushings and Washers

Case Study

A variety of jet engine components—from variable vanes to torque box/bell crank linkage arms—have relative motion that can benefit from the wear-resistant, low-friction properties of Vespel®.

Vespel® composites have demonstrated high performance in aerospace bushing and washer applications for more than 40 years, and our range of products allows us to customize material solutions to specific customer needs.

Application

- There are a wide variety of locations on a jet engine and aircraft where parts have relative motion that benefit from wear resistant, low friction materials.

- Common applications are variable stages and actuation systems in jet engine compressors, bleed valve systems, valves, and actuators for nacelles and aircraft surfaces.

Challenges

- Damage can occur to expensive metal components such as vanes from metal on metal engagement resulting in galling and locked components.

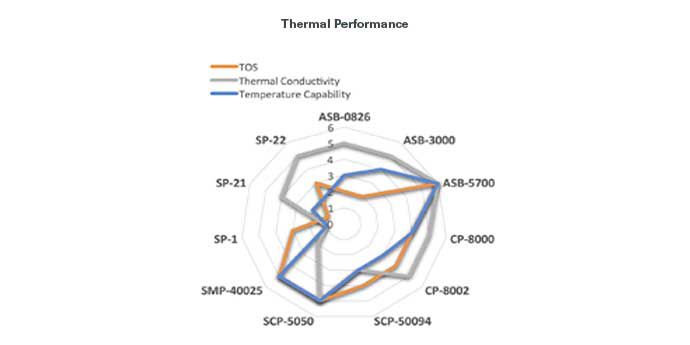

- Components need to withstand thermal excursions for duration of expected engine life with temperatures in excess of 600°F/315°C.

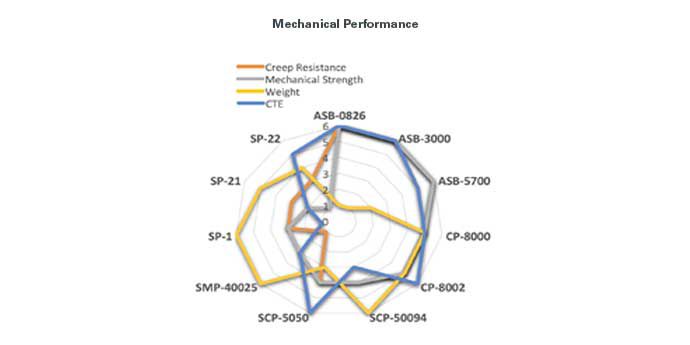

- Bushings need to withstand impact, cantilever loading, and accommodate designs with tight fits.

- Most jet engine applications do not have lubrication.

- Each application has a unique set of operating conditions and requirements.

Solution

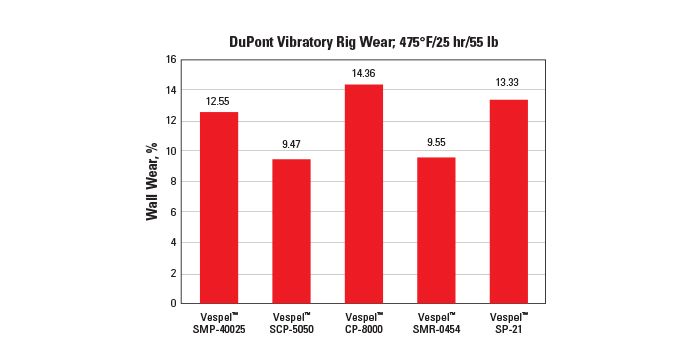

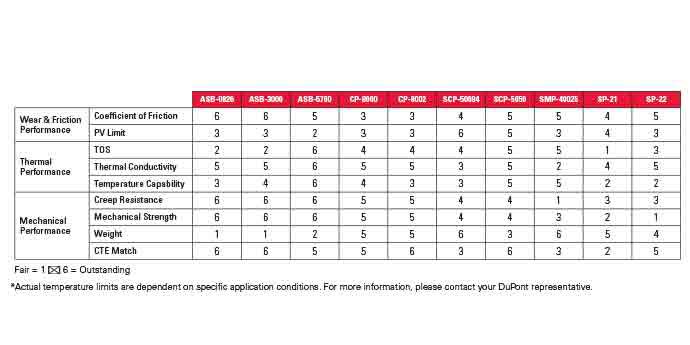

- DuPont™ Vespel® offers a wide variety of products that have demonstrated high performance on bushing and washer applications across turbines, engines, and aircraft for over 40 years (see selection guide).

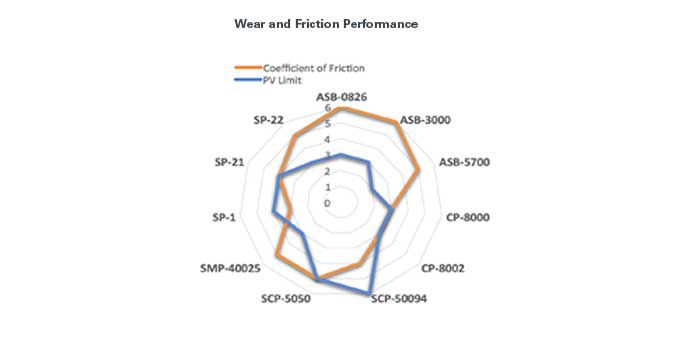

- Product selection can be optimized to help provide a customized solution to your unique application conditions.

Features and Benefits

- High temperature material capabilities in application environments in excess of 600°F/315°C.*

- Longer component life for higher cost mating components.

- Potential weight savings of 40% over aluminum and 75% over stainless steel and titanium due to lower density of composite materials.

- Lower friction vs. metal with dynamic coefficient of 0.2 or less.

- Fiber and metal reinforced product options for high load applications. ASB grades utilize metal retainers with low friction/wear resistant liners.

- Broad material options allow for customized solutions to help meet specific application requirements.

PRODUCT INFORMATION

Additional Information (1)